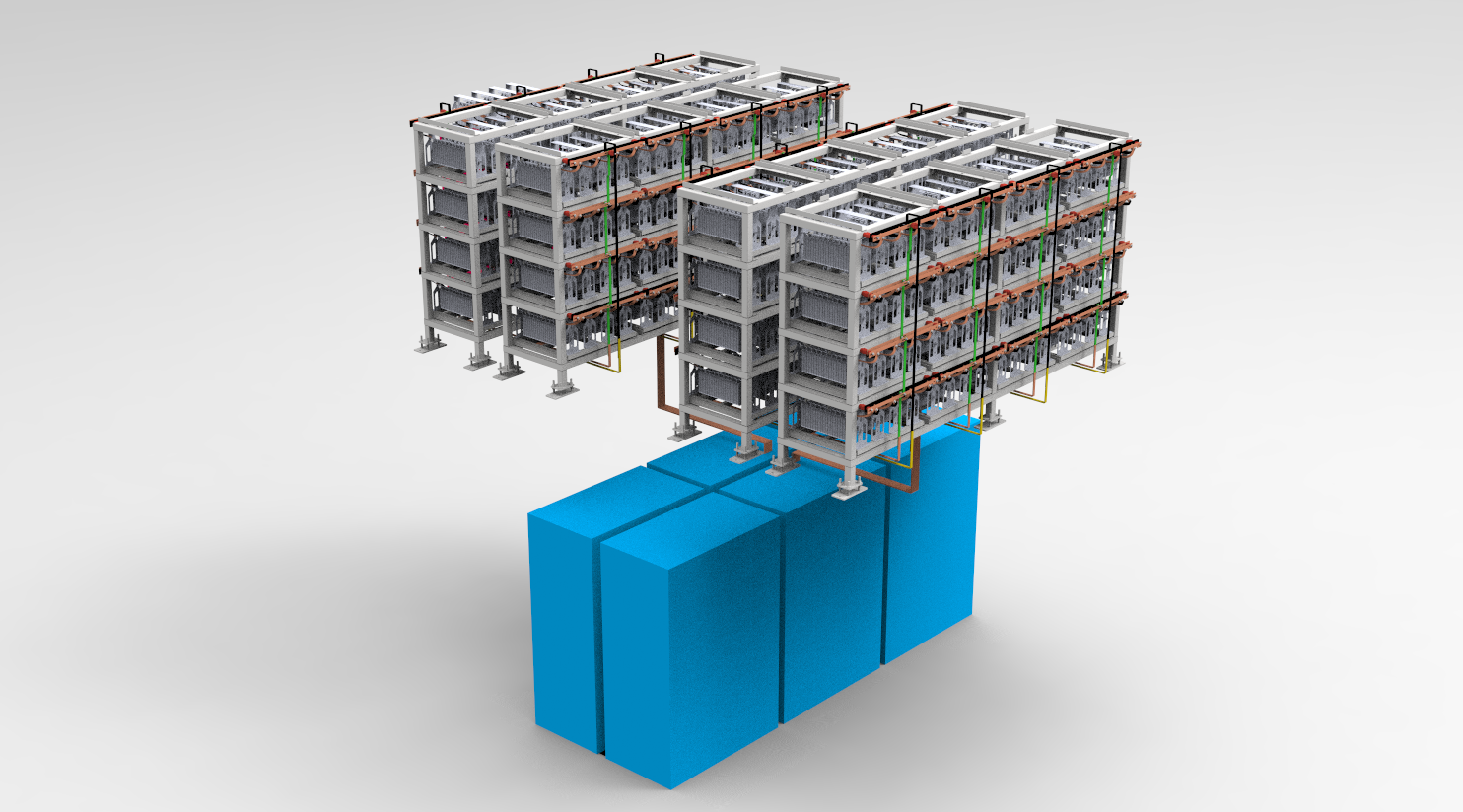

OCEM Power Electronics completed and presented the executive design of the first FDU device for the new DTT nuclear fusion reactor under construction at the ENEA research center in Frascati, after more than a year of work. FDUs are the “Fast Discharge Units”, powerful electronic systems to protect the 18 magnets that create the reactor’s toroidal magnetic field and discharge them very quickly in case of criticality or malfunction.

Signed in spring of 2022, the contract with Enea calls for OCEM to supply the three “safety units” by 2026, an order worth about 8 million euros that now moves to the construction phase.

In fact, the design was the most complex phase of OCEM PE’s work, partly because a critical component (an explosive circuit breaker) that is produced only in Russia and is no longer available due to the Russian-Ukrainian conflict had to be replaced in the process. Fast and accurate breaking time (on the order of a thousandth of a second) are provided by a fully electronic switch with no moving parts, which is completely redundant.

The other important innovation is the replacement of the usual banks of steel resistors with silicon carbide varistors (a ceramic and semiconductor material increasingly used in high-power electronics) capable of discharging the huge amount of energy from the magnets in about ten seconds, with times reduced by up to 70 percent compared to traditional resistors and with 20 percent less voltage and temperature.

These aspects make OCEM’s FDUs unique in the world, as pointed out by researchers from Enea’s Fusion and Nuclear Safety Technologies Department: “Compared to the protection systems mounted on ITER and JT-60SA magnets, our devices have technical innovations that make them safer, faster and more reliable. And, at the moment, they constitute a unique innovation in the world’s research landscape.”

The construction phase of the first FDU is now beginning in Crespellano; the unit is expected to be in Frascati, after factory testing, by the second half of 2024 and will initially be used to test different types of magnets in the experimental phase at the Frascati Coil Cold Test Facility, being set up near the main reactor, to verify and resolve any malfunctions before the final installation of the components in the tokamak.

Magnets are made of superconducting wires that store extremely high amounts of energy (2GJ) to generate the reactor’s toroidal field that can trap glowing plasma at 150 million degrees and prevent it from touching and damaging the reactor walls. In the event of problems with the magnets, the FDUs draw their current (42,500 A) and dissipate the energy, discharging them in seconds; they are thus the main protection system of a fusion power plant, its “life-saving device.”

Cover image’s copyright: DIRE

Crespellano, 20 September 2023